Services

MTD offers a wealth of Design and Consultancy experience to clients across the pharma and medical device sectors.

The company’s in-house team has a combined 80+ years of industry experience and are well positioned to develop and progress concept designs and designs for manufacture, ensuring all key project and product requirements are met on time and as needed. Different costing options are available (Rate per Hour or fixed project costs) to suit every budget and project requirements.

MTD has decades of experience working on R+D projects

Through a vast network of contacts in Academia and Research Faculties in Ireland and further afield can progress your R+D request in an efficient and capable manner, leveraging the latest advances in science and technology to ensure the best possible solution.

The team develops innovative, customer-focused manufacturing solutions by focusing on continuous process improvements and utilising the latest manufacturing hardware and software resources to ensure excellent research results and implement these results in the marketplace.

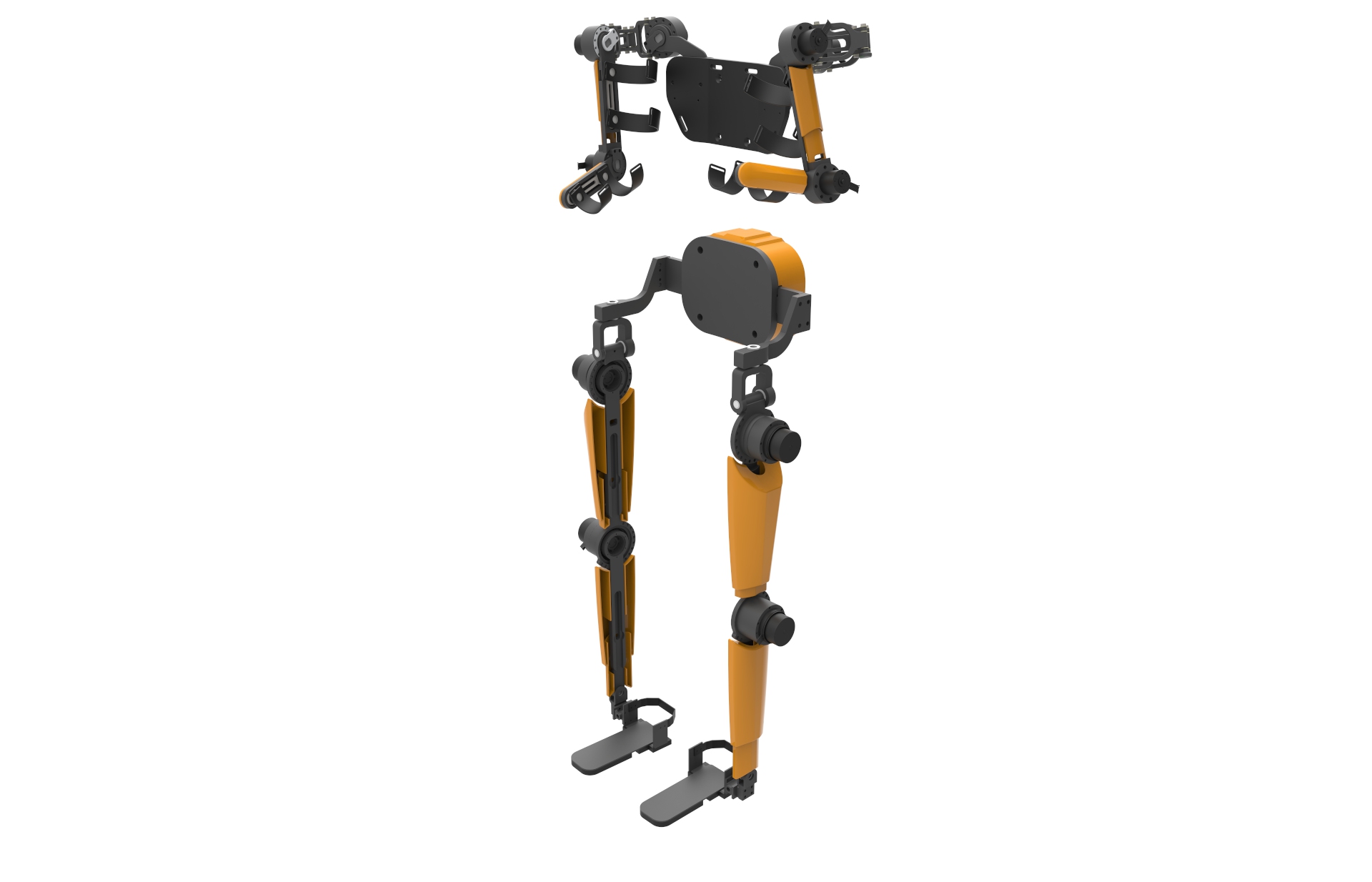

Axo Suit – Exoskeleton

AXO-SUIT was a three year project which began in October 2014 and was funded under the Active and Assisted Living (AAL) Joint Programme.

The project brought together 3 universities and 5 companies who were active and experienced in R&D. The aim of the project was to research personal mobility, reaching, and grasping requirements of elderly persons and develop a full body exoskeleton allowing them to continue managing their daily activities, as well as participating in local social activities while preserving their health and providing motivation to remain active and independent.

Research Partners: www.keepon.se

MTD’s in-house and state-of-the-art CNC manufacturing facility sets it apart from the rest.

With 5-axis machining capability, our “Best in Class” Lang Workholding and application tooling solutions is supplemented by quality inspection and certification capabilities, allowing the MTD team to machine, measure and verify production parts in an efficient and cost effective manner.

The MTD team is experienced in developing both 3D Printing prototypes and Post 3D print machining as needed.

Continual investment and training in the company’s in-house 3D printing capability, as well as alignment with leading external strategic 3D houses, ensures that MTD is well placed to support clients that wish to outsource their activities including 3D print prototyping, product development and finished part supply.

3d printers that we use are ultimaker filament printing and anycubic resin printer.